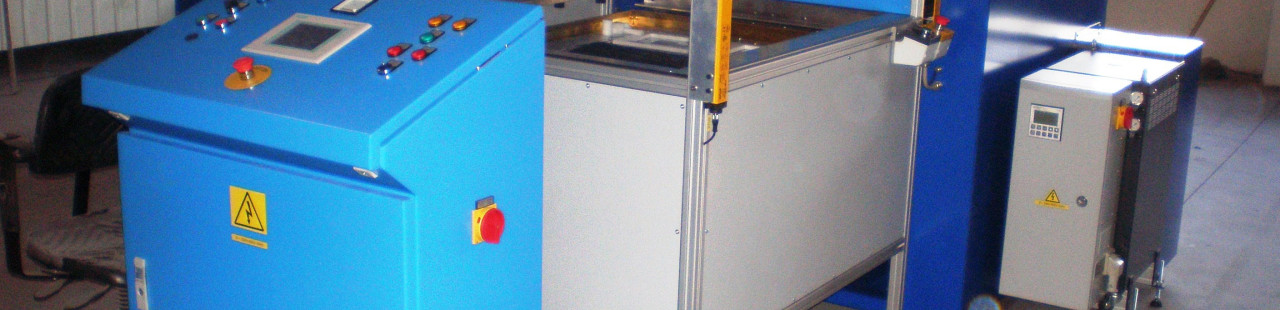

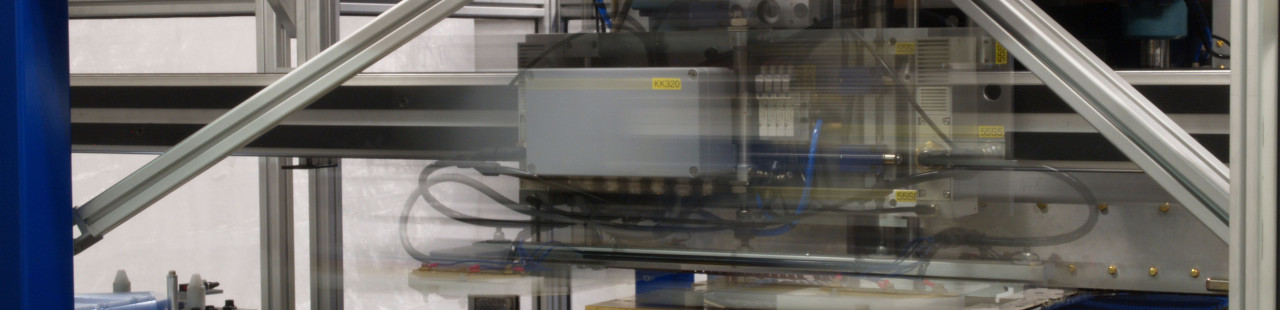

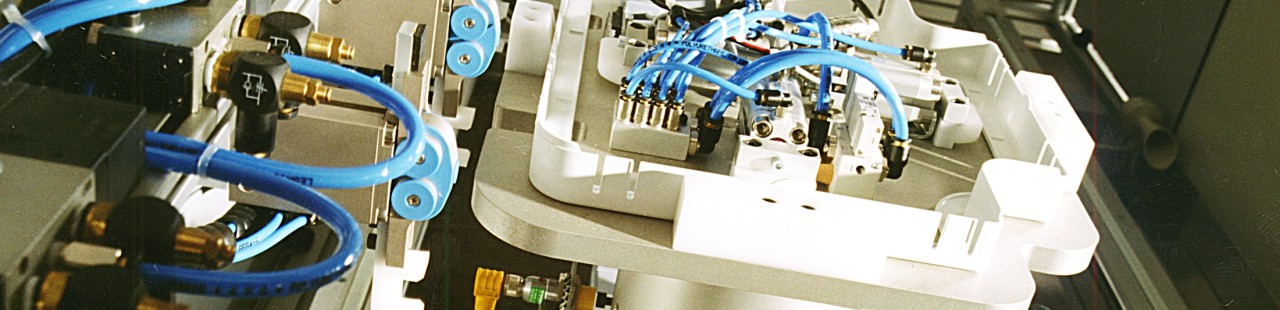

Welding electrodes and toolsets for various interior parts of passenger cars and trucks: for the production of car seat upholstery and car door upholstery, for pneumatic comfort seat systems systems in car seats, car luggage covers, for heel pads and logos on car mats, for the production of mattress systems in truck cabins, for insulation panels etc.

Recent Comments