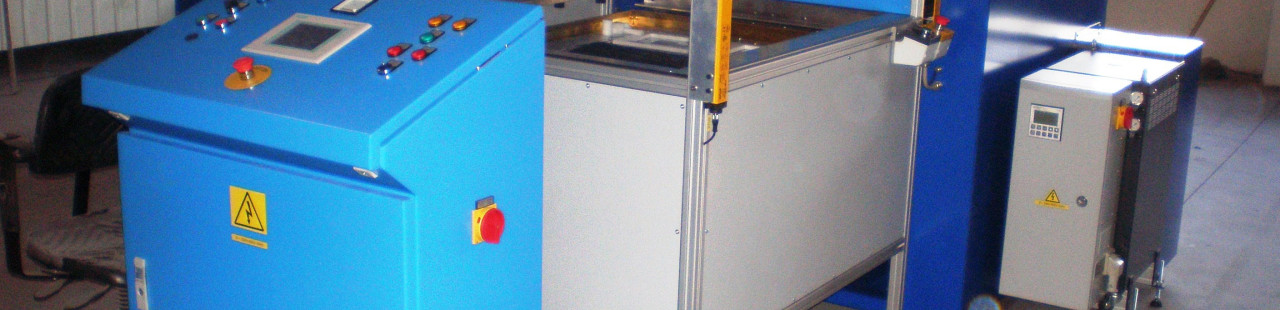

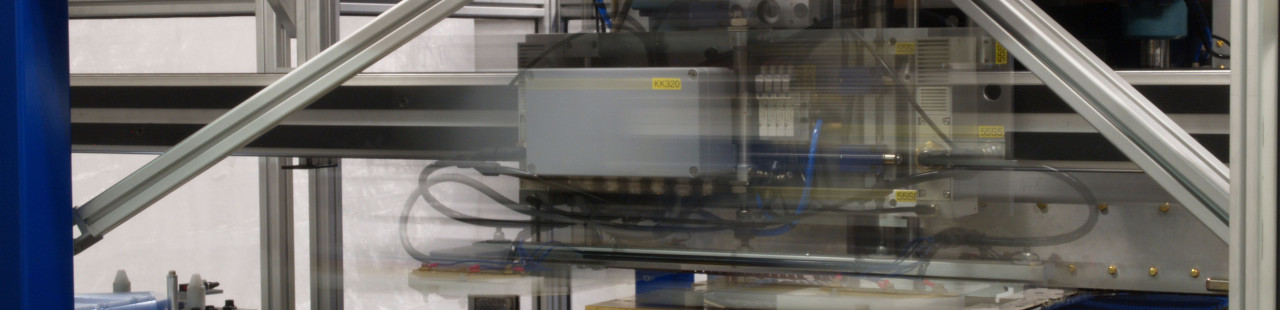

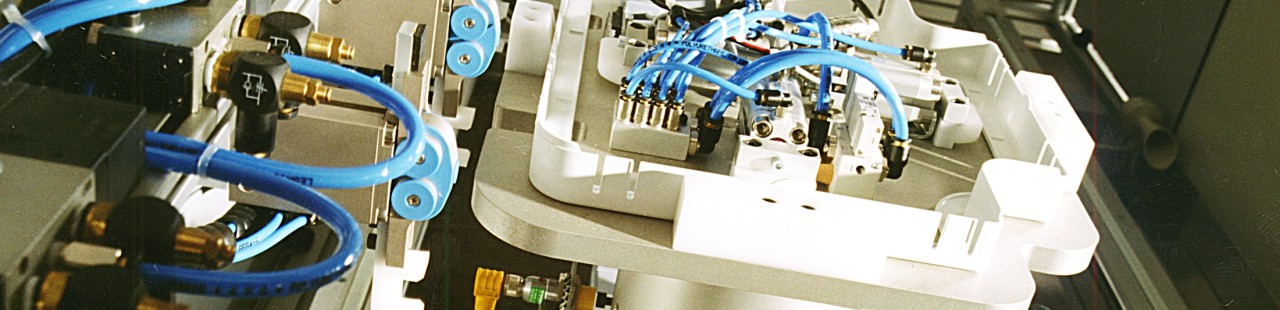

For a manufacturer of climate systems, we built and developed a special HF welding machine for the fully automatic assembling and welding of air heat exchangers. These air heat exchangers consist of a large number of pre-formed thin plastic sheets in right and left hand versions, which fully automatically alternate one by one, and sheet for sheet are welded onto each other. The machine contains:

- a high frequency generator;

- a double press for simultaneous assembling and welding of 2 air heat exchangers;

- a 2-station turntable system for simultaneous feeding and positioning of plastic sheets during the welding cycle;

- Pick & place systems for the feeding the various sheets during the welding cycle;

- Supply buffers

Recent Comments