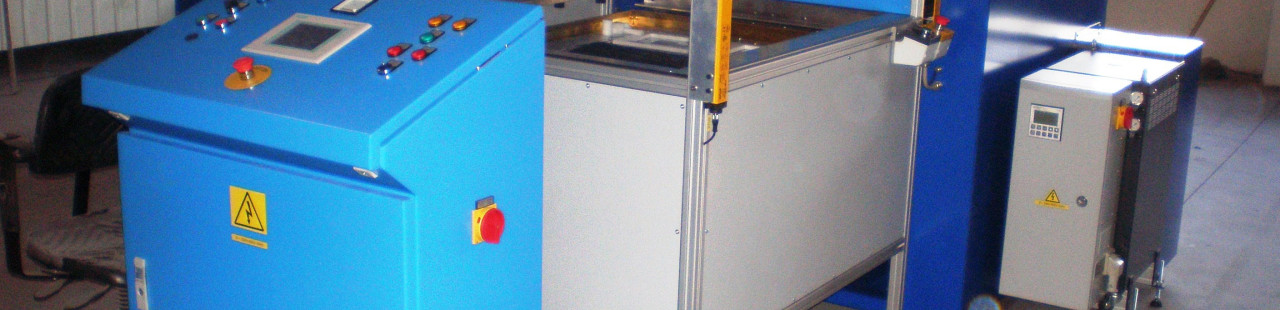

HF welding machine with automatic Shuttle Tray sliding system, standard available with a generator with 6-15kW power, and with pressing force of 10 to 50kN.

Specification options:

- Generator power 6 to 15kW, with servo-controlled auto-tuner, for very fast and accurate HF energy adjustment during the welding cycle.

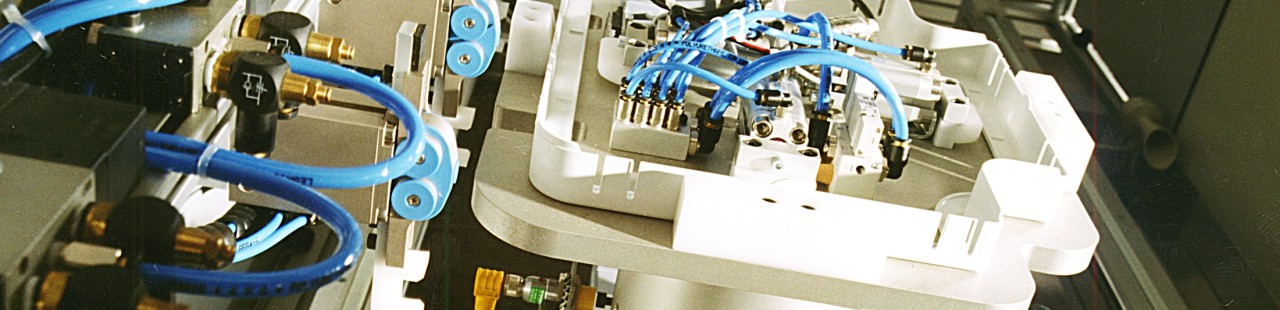

- Pressing force of 10 to 50kN, depending on the version chosen: pneumatic, hydraulic or with help from an electric servo-drive.

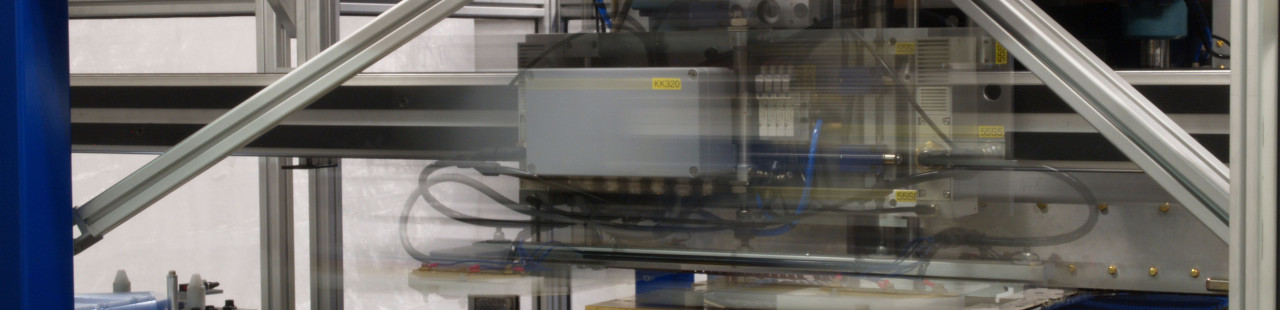

- Press provided with fully-closed EMC protection and anti-flash detection.

- Press platen weld surface 700 x 500 mm or 900 x 600 mm.

- Shuttle Tray sliding system with 2 automatically operated trays, fully protected with optical-electronic safety light curtain.

- Via a selection menu on the touch screen, 99 different products with associated welding settings can be entered and can be changed.

- Please feel free to contact us for extended specification possibilities and options (heating and/or cooling of the press platen and/or the trays, tool identification systems, graphic diagnosics of the welding cycles with data logging, etc.).

Recent Comments